Define Strength of Concrete

The strength of concrete refers to its ability to withstand loads without failing. It is a key property that determines the performance and durability of concrete in construction. The strength of concrete is typically measured in terms of compressive strength, which is the capacity of the concrete to resist compression forces. This is usually determined by testing concrete specimens in a laboratory after they have been cured for a specific period, typically 28 days. The strength of concrete is influenced by several factors, including the mix proportions of cement, water, aggregates, the quality of the materials used, the curing conditions, and the age of the concrete. Higher strength concrete is often used in structural applications where greater load-bearing capacity is required.

Compressive Strength of Concrete at 7 Days, 14 Days, 28 Days

At 7 days, concrete typically achieves about 60-70% of its ultimate 28-day strength. This early-stage strength is crucial for assessing the curing progress and ensuring that the concrete is hardening at the expected rate. However, the exact strength at 7 days can vary based on factors like the mix design, environmental conditions, and curing practices.

By 14 days, concrete usually reaches about 80-85% of its 28-day strength. This is a good indicator that the concrete is continuing to gain strength at an appropriate rate, though it is still expected to reach its full design strength by 28 days.

At 28 days, concrete is considered to have attained its full design strength, which is the standard timeframe used in construction to define the required compressive strength. For instance, if the specified compressive strength is 30 MPa, the concrete should reach 30 MPa at 28 days under standard curing conditions.

What is the Compressive Strength of Concrete?

The compressive strength of concrete is the most important factor in determining the load-bearing capacity of a concrete structure. It is typically measured after 28 days of curing, but it can also be measured at earlier ages. The compressive strength of concrete can range from as low as 1,000 psi to as high as 10,000 psi.

Range of Compressive Strength of Concrete

The range of compressive strength of concrete is given below based on concrete type and it's strength.

- Low-Strength Concrete: Below 20 MPa (about 2,900 psi)

- Standard or Normal-Strength Concrete: 20 MPa to 40 MPa (about 2,900 psi to 5,800 psi)

- High-Strength Concrete: More than 40 MPa (about 5,800 psi)

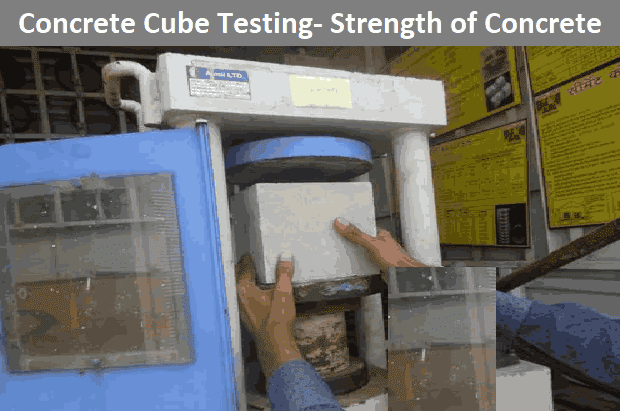

How to Measure the Compressive Strength of Concrete?

1. Concrete Cube Test: In this method, specimen of concrete cubes are subjected to a compression load in CTM or UTM.

2. Compressive Testing of Concrete Cylinders: This is the most widely used method for determining concrete strength. Cylindrical specimens, typically 6 inches in diameter and 12 inches tall, are prepared from fresh concrete and cured under controlled conditions. After the specified curing period, usually 28 days, the cylinders are placed between the platens of a compression testing machine and subjected to increasing compressive load until they fail. The compressive strength is calculated by dividing the maximum load by the cross-sectional area of the cylinder.

2. Concrete Core Test: In this method, specimen of concrete cores are cut from the structures and they are subjected to a compression load in CTM or UTM to find the breaking load, and the value is used to determine strength.

3. Ultrasonic Pulse Velocity (UPV) Test: This non-destructive method measures the time it takes for an ultrasonic pulse to travel through a concrete specimen. A higher UPV indicates a denser and stronger concrete. Correlations are established between UPV and compressive strength based on concrete type, age, and moisture content.

4. Rebound Hammer Test (Schmidt Hammer Test): This non-destructive method utilizes a rebound hammer to assess the in-situ compressive strength of concrete. The hammer is swung against the concrete surface, and the rebound distance is measured. A higher rebound distance indicates a stronger concrete. Correlations are established between rebound distance and compressive strength based on concrete type, age, and surface conditions.

5. Penetration Resistance Test: This non-destructive method measures the resistance of concrete to the penetration of a steel probe. The probe is driven into the concrete surface using a calibrated hammer, and the depth of penetration is recorded. A shallower penetration depth indicates a stronger concrete. Correlations are established between penetration depth and compressive strength based on concrete type, age, and surface conditions.

6. Maturity Method: This method estimates the compressive strength of concrete based on its maturity, which is a function of time and temperature. The maturity is calculated using a maturity function that takes into account the concrete mix design and curing conditions. Correlations are established between maturity and compressive strength based on concrete type, age, and temperature data.

Factors Affecting the Compressive Strength of Concrete

The compressive strength of concrete depends on factors such as the concrete mix design (proportion of ingredients), age of specimen, quality of materials, curing conditions, and testing procedures.

What is the Tensile Strength of Concrete? Flextural Strength

Tensile strength or flextural strength of concrete is the ability to resist tensile or pulling forces. The tensile strength of concrete is about 10% of its compressive strength. This means that concrete is much stronger in compression than in tension. The tensile strength of concrete is important for resisting cracking and spalling. So that, concrete is often reinforced with materials like steel to enhance its tensile strength. Tensile strength of concrete is measured in pounds per square inch (psi) or megapascals (MPa).

How to Measure the Tensile Strength of Concrete?

The tensile strength of concrete can be measured using following methods:

1. Splitting Test: In this method, cylindrical specimen of concrete is subjected to a compressive load while it is resting on two supports. The tensile strength is calculated from the load at which the specimen splits in half.

2. Beam Test: In this method, beam-shaped specimen of concrete is subjected to a load at its center through a designed rod in UTM. The tensile strength is calculated from the deflection of the beam.

What is the Shear Strength of Concrete?

The shear strength of concrete is the resistance to forces that tend to cause two opposite sides of a material to slide past each other. The shear strength of concrete is about 70% of its compressive strength.

What is Strength of Concrete Test?

Strength of concrete test is the process to know the ability of the hardened concrete to resist the compression load, tension load and shear stress. These test results are obtained from various test procedures like compression test on concrete cube or concrete core, tensile strength or flextural strength test on concrete beam and split strength test on the concrete cylinder.

Strength of Concrete Cube

Strength of concrete cube is determined by the compression test, in this the cube i placed under compression machine and load is provided. The maximum load at which cube breaks is noted down and the load is divided by the surface area of concrete cube. The result value is called as compressive strength of concrete. For flextural strength and split strength different procedures are used to determine the strength.

Effect on the Strength of Concrete over Time Period

As we can observe, the strength of concrete increases fast and then the strength of concrete increases slowly till its maximum strength. Th strength of concrete over long time starts decreasing because the bound of cement starts becoming weak.

How to Increase Strength of Concrete?

The strength of concrete can increase with several factors. Some of the factors are given below.

1. Water-to-Cement Ratio (W/C Ratio): The water-to-cement ratio is a critical factor affecting the strength of concrete. Generally, lower water-to-cement ratios result in higher compressive strength. Too much water can weaken the concrete, while a lower water content leads to better strength.

2. Curing Conditions: Proper curing is essential for concrete strength development. Adequate curing involves maintaining a favorable temperature and moisture level during the early stages of concrete setting and hardening. Well-cured concrete tends to achieve higher strength.

3. Quality of Materials: The quality of constituent materials, including cement, aggregates, and water, significantly influences concrete strength. Using high-quality materials ensures better overall performance.

4. Type and Quality of Cement: Different types of cement, such as Portland cement or blended cements, can impact concrete strength. Additionally, using cement with higher strength characteristics can contribute to stronger concrete.

5. Aggregate Properties: The type, size, shape, and gradation of aggregates affect the concrete's strength. Well-graded aggregates with good bonding properties can enhance the overall strength.

6. Concrete Mix Design: The proportions of cement, aggregates, and water in the concrete mix, known as the mix design, play a crucial role in determining its strength. A well-designed mix, considering the specific requirements of the project, contributes to better strength performance.

7. Admixtures: Admixtures are chemicals that can be added to concrete to modify its properties. Certain chemical admixtures, such as superplasticizers or accelerators, can be used to modify the properties of fresh or hardened concrete. Proper use of admixtures can enhance workability, durability, and, in some cases, strength.

8. Age of Concrete: Concrete continues to gain strength over time. While the early curing period is critical, the concrete's strength will continue to develop over weeks and months.

9. Temperature: The temperature during curing and early stages of concrete hardening can influence its strength. Generally, higher curing temperatures contribute to faster strength development, but extreme conditions should be avoided.

10. Mixing and Placing Practices: Proper mixing and placing of concrete ensure uniform distribution of materials, reducing the likelihood of weak zones. Adequate consolidation during placement helps eliminate air voids that could weaken the concrete.

What is Strength of Concrete in One Day?

The strength of concrete in 1 day is approximately 15-20% of its 28-day strength. This means that if a concrete mix has a 28-day strength of 4,000 psi, it will have a strength of around 600-800 psi after one day.

Concrete gains strength rapidly at first, and then more slowly over time. This is because the hydration process, which is the chemical reaction that causes concrete to harden, is most active in the first few days. After about 28 days, the hydration process has slowed down significantly, and the concrete has reached most of its potential strength.

Age of Cube vs Strength of Cube

| Age (Days) | Strength |

|---|---|

| 1 Day | 15-20% Strength |

| 3 Days | 40% Strength |

| 7 Days | 65% Strength |

| 14 Days | 90% Strength |

| 28 Days | 99% Strength |

FAQs- Compressive Strength of Cube

What is Strength of Concrete in 3 Days?

The strength of concrete at 3 days is 40% (minimum) of the nominal strength of concrete.

What is Strength of Concrete in 7 Days?

The strength of concrete at 7 days is 65% (minimum) of the nominal strength of concrete.

What is Strength of Concrete in 14 Days?

The strength of concrete at 14 days is 90% (minimum) of the nominal strength of concrete.

What is Strength of Concrete in 21 Days?

The strength of concrete at 21 days is 96% (minimum) of the nominal strength of concrete.

What is Strength of Concrete in 28 Days?

The strength of concrete at 28 days is 99% (minimum) of the nominal strength of concrete grade.

What is Strength of Normal Concrete?

Since, the grade of normal concrete used in RCC structure is M20 which compressive strength at 28 days is minimum 20 N/mm².

What is Strength of Concrete in MPa?

Strength of concrete is measured in MPa (Mega Pascal), i.e. compressive strength of concrete in N/mm². If there is M25 grade of concrete, its compressive strength at 28 days is 25 MPa or 25 N/mm².

Strength of Concrete After 7 Days

The strength of concrete at 7 days is 65% (minimum) of the nominal strength of the concrete.