In this blog post we will discuss about 0.2% stress of steel. Read the complete blog post to know why 0.2% proof stress steel is important.

What is Proof Stress?

Proof stress is a measure of the minimum stress that a material can withstand before it begins to permanently deform. In the case of steel, proof stress is the stress at which a small, permanent deformation (typically 0.2% of the original length) occurs in the material. This is used as a measure of the material's strength and ductility.

What is 0.2% Proof Stress of Steel? Yield Strength of Steel

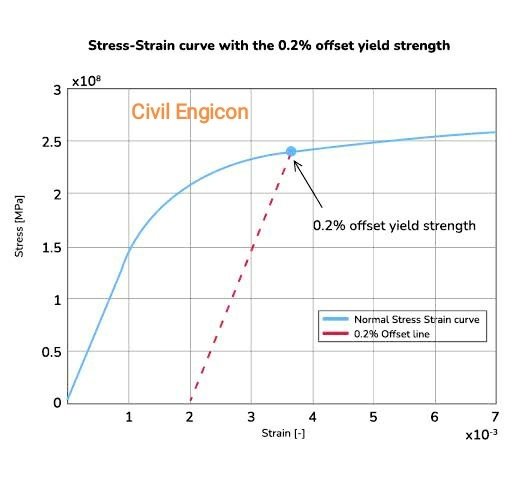

0.2% proof stress, also known as yield strength, is the stress level at which a material begins to deform as plastic. For steel, the 0.2% proof stress is an important mechanical property that indicates the point at which the material changes behavior from elastic to plastic.

So, 0.2% proof stress is a measure of the steel's ductility or ability to deform without breaking. 0.2% proof stress, also known as the 0.2% offset yield strength, is a mechanical property used to describe the strength of a material, particularly metals like steel. It is a measure of the stress at which a material begins to exhibit permanent deformation (plastic deformation) after being subjected to an applied load.

What is 0.2% Proof Stress of Steel?

The 0.2% proof stress of steel refers to the amount of stress that can be applied to a steel sample before it begins to permanently deform. It is typically measured by applying a tensile load to a small sample of steel and measuring the amount of strain (deformation) that occurs.

- The term "0.2% proof stress refers to the specific point at which the steel begins to deform at a strain of 0.2%. This is considered to be the point at which the steel is no longer able to withstand the applied stress and will begin to permanently stretch or bend.

- The 0.2% proof stress is a measure of the steel's ductility or ability to deform without breaking. A higher 0.2% proof stress indicates that the steel can withstand more stress before deforming, making it more ductile.In practical applications, the 0.2% proof stress of steel is used to determine the appropriate load-bearing capacity for structures made of steel as well as to assess the overall strength and durability of steel products.

Why 0.2% Proof Steel is Important?

The 0.2% proof stress plays a vital role in ensuring the safety, reliability, and performance of materials and structures. It's a key parameter used in engineering design, quality control, and material selection to ensure that products and structures can withstand loads without experiencing plastic deformation or failure.

1. Yield Point Identification

The 0.2% proof stress is used to define the yield point of a material. The yield point is the stress level at which a material transitions from elastic deformation (where it returns to its original shape when the load is removed) to plastic deformation (where it undergoes permanent, non-reversible deformation). This transition is critical for determining how a material behaves under load and for engineering safe structures.

2. Design and Engineering

Engineers and designers use the 0.2% proof stress to ensure that structures and components are designed to withstand loads without experiencing plastic deformation or failure. It helps determine the maximum stress a material can endure while remaining within its elastic range.

3. Safety

Understanding the 0.2% proof stress is essential for ensuring the safety and reliability of structures, equipment, and products. It guides engineers in selecting appropriate materials for various applications, preventing overloading and avoiding catastrophic failures.

4. Material Selection

Different materials and alloys have varying 0.2% proof stress values. This property is a key factor in selecting the right material for a specific application. Materials with higher proof stresses are more suitable for applications requiring strength and load-bearing capacity.

5. Quality Control

Manufacturers use the 0.2% proof stress to ensure the consistency and quality of their products. By performing tensile tests and determining the proof stress, they can verify that the material meets the specified standards and will perform as expected.

6. Structural Integrity

In industries such as construction, aerospace, automotive, and manufacturing, the 0.2% proof stress is critical for assessing the structural integrity of components, assemblies, and materials used in these sectors.

7. Stress Analysis

Engineers use the 0.2% proof stress in stress analysis to calculate factors of safety and predict the behavior of materials under various loads and conditions.

8. Standardization

The 0.2% proof stress is a standardized property that allows for consistent comparison and characterization of materials across different applications and industries.