In this blog we have discussed about expansion joints in construction with their types, advantages and disadvantages, purpose, and uses of expansion joints.

What are the Expansion Joints in Construction? Types, Advantages

Expansion joints in construction are deliberate separation or gap introduced in a structure, such as a concrete beam, to accommodate the natural expansion, contraction, and movement that can occur due to factors like temperature changes, moisture variations, or external loads. This joint allows the structure to flex and shift slightly without causing cracks or damage.

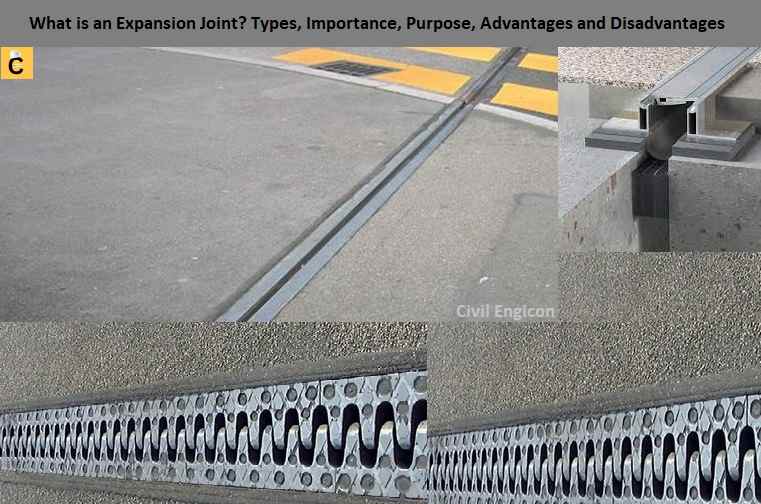

Expansion Joints In Construction

Expansion joints in construction are like safety seams that let concrete beams move without breaking due to temperature changes. They have benefits like preventing cracks and extending the beam's life, but they can also lead to maintenance needs and aesthetic concerns. So, they are a bit like a trade-off – they solve some problems while introducing others.

Uses of Expansion Joints in Construction

Expansion joints are used to maintain the integrity and safety of structures by preventing the buildup of stress that could lead to structural failure or aesthetic issues. They are like controlled gaps that help structures adapt to changing conditions without breaking.

Types of Expansion Joints in Building Construction

The following types of expansion joints are commonly used in various structures. Each type of expansion joint serves a specific purpose and is chosen based on factors like the type of structure, the amount of expected movement, and the environmental conditions it will face.

1. Dilatation or Expansion Joints

This is the most common type of expansion joint. It's a gap between two parts of a structure that allows them to expand and contract without causing damage. These joints are often used in concrete pavements, bridges, and buildings.

2. Isolation Joint

This joint completely separates different parts of a structure. It's used to prevent the transfer of loads or vibrations from one part to another. For example, it's used between a building's foundation and the walls to avoid cracks due to settling.

3. Contraction Joint

While not exactly an expansion joint, this type of joint controls cracks that occur due to concrete shrinkage as it cures. These joints are usually placed at regular intervals to guide where cracks will form.

4. Sliding Joint

Often used in bridges, these joints allow one section of a structure to slide over another. This accommodates movements caused by temperature changes or other external factors.

5. Modular Expansion Joint

These joints are often used in large structures like bridges to accommodate significant movements. They consist of several modules that can expand and contract independently.

6. Compression Seal Joint

This type of joint is used to seal gaps between two structures while still allowing for slight movement. It's often seen in parking garages or other structures with multi-story sections.

7. Finger Joint

This type of expansion joint is used in roads, bridges, or buildings. It consists of multiple "fingers" that interlock, allowing for movement while maintaining a smooth surface.

8. Elastomeric Joint

These joints use flexible materials like rubber to absorb movements and vibrations. They're commonly used in structures where the movement isn't very large.

Types of Expansion Joints In Bridges

In the bridges, expansion joints are crucial for accommodating the movement caused by temperature changes, traffic loads, and other factors.

The choice of the type of expansion joint depends on factors such as the bridge's size, location, expected movement, and the specific engineering requirements of the project. Different types of joints have their own advantages and limitations, and the selection is made based on the bridge's design and intended use. Here are some common types of expansion joints used in bridges:

1. Modular Expansion Joints

These consist of multiple modules that allow the bridge to expand and contract. They can handle both longitudinal and transverse movements and are suitable for large bridges.

2. Finger Joints

Finger joints consist of interlocking steel plates or bars that allow limited movement while maintaining a smooth surface. They're often used in road bridges.

3. Sliding Plate Joints

Sliding plate joints use steel plates that slide against each other, accommodating longitudinal movements. They're commonly used in highway bridges.

4. Strip Seal Joints

Strip seal joints consist of rubber strips inserted between steel or concrete members. They allow small movements while providing a watertight seal.

5. Elastomeric Joints

These joints use flexible materials like rubber to absorb movement. They're suitable for smaller bridges or locations with less movement.

6. Compression Seal Joints

Compression seals use compressible materials to seal the gap between bridge sections while still allowing limited movement. They're often used in multi-span bridges.

7. Fiber Reinforced Polymer (FRP) Joints

FRP materials can be used to create flexible joints that accommodate movement while being lightweight and corrosion-resistant.

8. Cross-Framed Expansion Joints

These joints consist of diagonal braces that allow the bridge to expand and contract while maintaining structural stability.

9. Roller Joints

Roller joints use rollers that allow bridge sections to move longitudinally. They're commonly used in situations where one end of the bridge is fixed and the other can move.

10. Pot Bearings

While not traditional expansion joints, pot bearings are used to support the bridge while allowing for controlled movement. They're often used in bridge piers.

Purpose of Expansion Joints in Construction

Expansion joints in construction act as "safety valves" that allow the material to move naturally without causing damage. They are crucial for maintaining the structural integrity, safety, and appearance of concrete structures over time.

The purpose of expansion joints in concrete is to accommodate the natural expansion, contraction, and movement of the material due to various factors. These joints are strategically placed gaps or spaces within the concrete structure that allow it to flex and shift without causing cracks or damage. Also, you can see the importance of expansion joints in building and bridges in this post.

Importance of Expansion Joint in Building

Expansion joints are essential for maintaining the safety, appearance, and longevity of buildings. They provide a controlled way for structures to handle movement and changes, thereby reducing the risks associated with uncontrolled cracking and stress buildup.

1. Preventing Cracks

Buildings are subject to temperature changes, humidity variations, and settling. These factors can cause materials like concrete to expand and contract. Without expansion joints, these movements could lead to unsightly and potentially structurally compromising cracks.

2. Structural Integrity

By allowing controlled movement, expansion joints help maintain the structural integrity of a building. They reduce the stress that can accumulate due to temperature-related expansion and contraction.

3. Safety

A well-designed and implemented expansion joint system ensures that the building remains safe for occupants. It prevents the formation of large, unexpected cracks that could compromise the overall stability of the structure.

4. Aesthetics

Expansion joints are strategically placed to minimize their visibility. While they might still be noticeable to some extent, they help maintain a more visually appealing appearance than random, unplanned cracks.

5. Longevity

Properly designed and maintained expansion joints can extend the lifespan of a building. By minimizing the wear and tear caused by movement-related stresses, the building's components, such as walls, floors, and ceilings, can last longer.

6. Maintenance Reduction

Buildings without expansion joints would require more frequent maintenance due to the greater likelihood of cracks forming. Well-maintained expansion joints reduce the need for constant repairs and maintenance work.

7. Flexibility

Expansion joints provide flexibility for a building to adapt to changing conditions. This is especially important in regions with significant temperature fluctuations, as materials expand and contract more in response to temperature changes.

8. Energy Efficiency

In some cases, expansion joints can contribute to energy efficiency. They allow the building to expand and contract without creating gaps that would compromise insulation, helping to maintain the building's energy performance.

9. Mitigating Vibrations

Buildings can experience vibrations from various sources, including nearby traffic or machinery. Expansion joints help absorb some of these vibrations, preventing them from propagating through the entire structure.

10. Regulatory Compliance

Many building codes and regulations mandate the use of expansion joints in certain types of structures and in specific locations. Using proper expansion joints ensures compliance with these regulations.

Advantages of Expansion Joints in Construction

Find the below disadvantages of expansion joints in construction.

1. Prevent Cracks

Expansion joints allow controlled movement, reducing the risk of unsightly and potentially harmful cracks in structures due to temperature changes and other factors.

2. Structural Integrity

By accommodating movement, expansion joints help maintain the structural integrity of a building or other structure. They prevent stress buildup that could lead to structural damage or failure.

3. Safety

Preventing cracks and structural damage enhances the safety of the building for occupants. It reduces the chances of sudden collapses or accidents caused by compromised structural elements.

4. Aesthetic Appeal

While not completely eliminating their visibility, properly designed expansion joints are more aesthetically pleasing than random cracks. They allow for a more uniform appearance, especially in architectural structures.

5. Longevity

Structures with expansion joints can have a longer lifespan since the controlled movement reduces wear and tear on materials.

6. Reduced Maintenance

By minimizing the development of cracks and structural issues, expansion joints can lower the need for frequent maintenance and repairs.

Disadvantages of Expansion Joint in Construction

Find the below disadvantages of expansion joints in construction.

1. Extra Cost

Installing expansion joints adds to the construction cost due to the materials, design, and labor involved in their installation.

2. Maintenance Needs

While they reduce overall maintenance, expansion joints themselves may require occasional maintenance, such as cleaning or replacing worn parts.

3. Water and Debris Entry

The gaps created by expansion joints can allow water, dirt, and debris to enter, potentially leading to deterioration or corrosion over time.

4. Aesthetic Concerns

While designed to be visually unobtrusive, expansion joints can still be noticeable and may affect the overall appearance of the structure.

5. Complex Construction

Planning and installing expansion joints correctly can be complex and require expertise. Poorly designed or executed joints might not function as intended.

6. Limiting Design

In some cases, expansion joints can limit the design possibilities of a structure, particularly if architects and designers need to work around their placement.