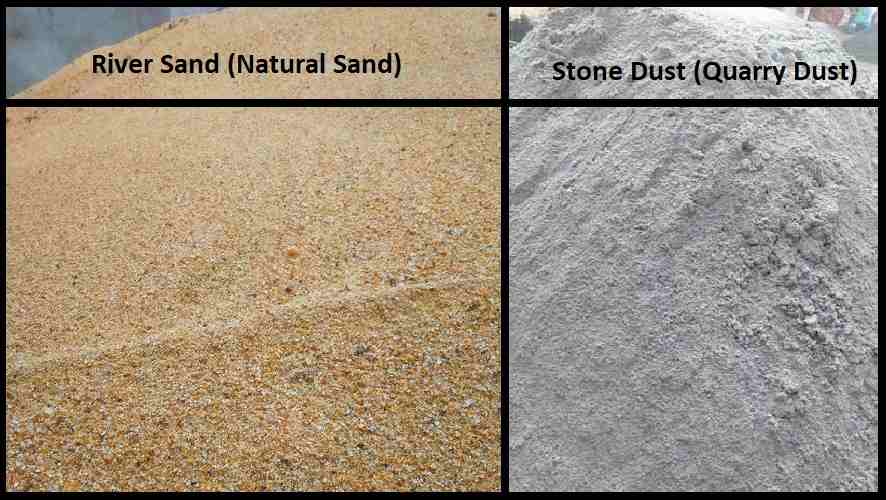

Stone Dust Vs River Sand- Which is Best For Construction?

Both stone dust and river sand have particles smaller than 4.75 mm. The size of the particles affects the strength and workability of the concrete. The choice between river sand and stone dust depends on several factors like the particle size and shape, cost, durability and availability of the material. Both materials have their advantages and disadvantages and the choice ultimately depends on the specific requirements of the construction project. Choosing the right building materials is to ensuring the safety, durability and overall quality of the structure.

|

| Stone Dust Vs River Sand |

About River Sand

River sand is a naturally occurring material that is extracted from river beds. It is primarily composed of fine granules that are smooth and rounded due to erosion over time. River sand is often used as a key ingredient in the production of concrete as it helps to improve the workability and strength of the mixture. It is also used for various other construction applications such as plastering and masonry work.

About Stone Dust or Quarry Dust

Stone dust or quarry dust is a byproduct of crushing stone for use in construction. It is composed of finely crushed stone particles that are angular in shape. Stone dust is often used as a base material for patios, walkways and driveways. It helps to provide a stable and level surface where it is leveled. It is used in concrete as replacement of river sand or natural sand.

Stone Dust (Quarry Dust) Vs River Sand (Natural Sand)

When it comes to comparing river sand and stone dust, there are several factors to consider. The first factor is the particle size and shape. River sand is made up of smooth and rounded particles which makes it easier to work with and provides better workability in concrete. Stone dust is composed of angular particles which can make it more difficult to work with and can reduce the workability of concrete.

In Terms of Cost

Another factor to consider is the cost. River sand is generally more expensive than stone dust, as it requires more effort and resources to extract from river beds. Stone is a byproduct of stone crushing and is often available at a lower cost.

In Terms of Durability

In terms of durability, both river sand and stone dust are relatively durable materials. But the river sand is more resistant to erosion and weathering due to its smooth and rounded particles which help to prevent the material from breaking down over time. Stone dust is more prone to erosion and may require more frequent maintenance to ensure its longevity.

In Terms of Availability

The availability of the material is also an important consideration. River sand is often in high demand and in some areas its extraction has caused environmental concerns. Stone dust is readily available in many locations and can be easily sourced.

Properties of Stone Dust Vs River Sand

Both stone dust and river sand are commonly used as fine aggregates in concrete. However, there are some differences between the two that can affect the performance of the concrete.

Table of Stone Dust Vs River Sand

| Property | Stone Dust (Quarry Dust) | River Sand (Natural Sand) |

|---|---|---|

| Particle Shape | Angular | Angular |

| Particle Size | <4.75mm | <4.75mm |

| Specific Gravity | 2.40 - 2.75 | 2.60 - 2.80 |

| Fineness Modulus | 2.40 - 2.80 | 2.40 - 2.80 |

| Durability | High | Moderate to High |

| Workability | Poor | Good |

| Compressive Strength | Higher than river sand | Lower than stone dust |

| Cost | Generally cheaper than river sand | Generally more expensive than stone dust |

Particle Shape

Stone dust has angular particles while river sand has rounded particles. Angular particles tend to interlock and bond better with the cement paste, providing better strength to the concrete. On the other hand, rounded particles allow for more movement between particles, providing better workability to the concrete.

Particle Size

Both stone dust and river sand have particles smaller than 4.75mm. The size of the particles affects the strength and workability of the concrete.

Specific Gravity

The specific gravity of stone dust is between 2.40 and 2.75 while the specific gravity of river sand is between 2.60 and 2.80. The higher specific gravity of river sand indicates that it contains more heavy minerals, which may affect the overall quality of the concrete.

Fineness Modulus

The fineness modulus of both stone dust and river sand is between 2.40 and 2.80. The fineness modulus is an indicator of the fineness or coarseness of the aggregate and it affects the workability and strength of the concrete.

Durability

Stone dust has high durability due to its angular particles that can interlock and bond well with the cement paste. River sand has moderate to high durability but it may contain impurities that can affect the durability of the concrete.

Workability

River sand has better workability than stone dust due to its rounded particles that allow for more movement between particles. Stone dust has poor workability due to its angular particles that can make the mix difficult to handle and compact.

Compressive Strength

Stone dust generally provides higher compressive strength to the concrete than river sand due to its angular particles that can interlock and bond well with the cement paste.

Cost of Sand

Stone dust is generally cheaper than river sand due to its availability as a byproduct of stone crushing. River sand is generally more expensive than stone dust due to its limited availability and transportation costs.

Disadvantages of Stone Dust

Stone dust has several advantages as a fine aggregate in concrete. It also has some disadvantages that should be considered. Here are some of the main disadvantages of using stone dust in concrete:

Poor Workability

As mentioned earlier, stone dust has angular particles that can make the mix difficult to handle and compact. This can result in poor workability which can make it difficult to achieve a smooth and uniform surface finish.

Dust and Respiratory Issues

Stone dust can be a respiratory irritant when it becomes airborne during the crushing process or while handling it. This can cause breathing difficulties and other respiratory problems, especially if protective measures are not taken.

Higher Water Demand

Stone dust has a high surface area and can absorb more water than sand, which can lead to a higher water demand in the mix. This can affect the workability and strength of the concrete if the water-to-cement ratio is not properly adjusted.

Reduced Cohesion

Due to its angular shape, stone dust has less cohesion than sand. This can result in a less cohesive mix that may be prone to segregation and bleeding.

Risk of Alkali Silica Reaction

Stone dust may contain reactive minerals that can react with the alkaline cement paste, leading to an alkali silica reaction (ASR). ASR can cause the concrete to expand and crack over time, reducing its durability and strength.

Limited Availability

Stone dust is not available everywhere, and its availability can be dependent on the location of stone crushing plants. This can make it difficult to source and transport especially for larger construction projects.