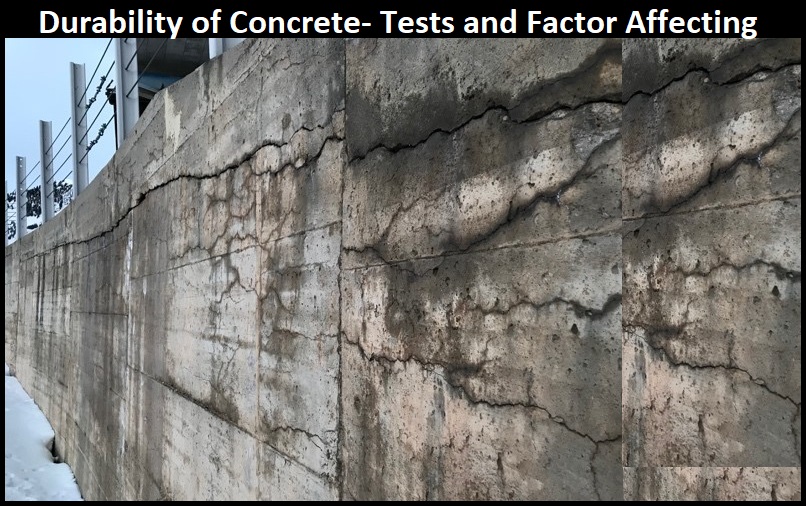

Concrete is a durable material, but it can be susceptible to deterioration over time. This is especially true in harsh environments, such as coastal areas or areas with extreme temperatures. To ensure that concrete structures last for their intended lifespan, it is important to test their durability.

What is Durability of Concrete? Tests and Factor Affecting

Durability of concrete is the ability of concrete to resist environmental conditions, chemical attacks, and physical wear over time. Durable concrete structure can maintain its integrity, strength, and appearance throughout its intended service life. There are several factors can affect the durability of concrete, and various tests are conducted to assess its resistance to different forms of deterioration, some of the most common tests are RCPT (Rapid Chloride Penetration Test), Water Permeability Test, Freeze-Thaw Test, and Sulfate Resistance Test. Read this complete blog post to understand well.

What is Durability of Concrete?

Since, concrete is a porous material, which means that it can absorb water and other liquids. This can lead to a number of problems. Durability of concrete is the ability of concrete to resist weathering action, chemical attack, abrasion, and other conditions. Durability determines the lifespan and serviceability of concrete structures.

Tests for Durability of Concrete

There are various direct and indirect tests performed to determine the durability of concrete. These tests are given below.

Compressive Strength Test For Durability of Concrete

Though not a direct durability test, compressive strength is indicative of the concrete's ability to withstand loads and resist deterioration.

Permeability Test For Durability of Concrete

Determines the ability of concrete to resist the penetration of water or aggressive substances. Common tests include the water permeability test and the chloride penetration test.

Rapid Chloride Ion Penetration Test (RCPT)

Measures the resistance of concrete to the penetration of chloride ions, which can cause corrosion of reinforcing steel.

Carbonation Resistance Test

Evaluates the resistance of concrete to carbon dioxide penetration, which can lead to carbonation and subsequent deterioration.

Alkali-Silica Reaction (ASR) Test

Identifies the potential for alkali-silica reaction, a chemical reaction that can cause expansion and cracking in concrete.

Sulfate Resistance Test

Assesses the resistance of concrete to sulfate attack, which can lead to the deterioration of concrete in sulfate-rich environments.

Freeze-Thaw Resistance Test

Evaluates the ability of concrete to withstand cycles of freezing and thawing without significant damage.

Abrasion Resistance Test For Durability of Concrete

Measures the resistance of concrete to surface wear and abrasion.

Importance of Durability of Concrete

Testing the durability of concrete is important for a number of reasons. First, it helps to ensure that concrete structures will last for their intended lifespan. Second, it helps to reduce the risk of costly repairs and maintenance. Third, it helps to protect the public from safety hazards.

Example:

If a concrete bridge is not durable enough, it could collapse and cause serious injuries or death. Similarly, if a concrete seawall is not durable enough, it could be damaged by storms and flooding, which could lead to coastal erosion and property damage.

By testing the durability of concrete, engineers can ensure that concrete structures are safe and will last for many years to come.

Factors Affecting the Durability of Concrete

There are various factors affecting the durability of concrete, see below.

Water-Cement Ratio (W/C Ratio)

As per experiments, lower water-cement ratio generally results in a more durable concrete. Excess water can lead to increased porosity and reduced strength. Hence, do not use more water than requirement.

Curing Conditions

Proper curing of concrete helps to prevent cracking and enhances the strength and durability of concrete. Inadequate curing of concrete can lead to surface defects and reduced resistance to environmental conditions.

Aggregate Quality

The aggregates (coarse aggregates and fine aggregate) used in the concrete mixture, should be free from impurities and should not react chemically with the concrete. Poor quality aggregates can contribute to deterioration, hence always use good quality of aggregates.

Air Entrainment

Adding air-entraining agents can improve the freeze-thaw resistance of concrete by creating tiny air bubbles that relieve internal pressure.

Chemical Admixtures

Some admixtures, such as corrosion inhibitors, can enhance the resistance of concrete to chemical attacks and corrosion.

Concrete Cover

Adequate cover over reinforcement bars protects them from corrosion, improving the overall durability of the structure.

Temperature and Climate

Extreme temperatures, cycles of freezing and thawing, and exposure to harsh climates can impact the durability of concrete.

Quality of Construction

Proper construction practices, including correct mixing, placing, and finishing of concrete, play a crucial role in ensuring durability.

How to Improve the Durability of Concrete?

There are a number of things that can be done to improve the durability of concrete. Some of the most common things are:

Using a Low W/C Ratio

A low w/c ratio produces a denser concrete with fewer pores. This makes the concrete less permeable to water and other harmful substances.

Using High Quality Aggregates

Aggregates are the sand and gravel that make up the majority of concrete. High-quality aggregates are less likely to contain impurities that could damage the concrete.

Using Admixtures

Admixtures are chemicals that can be added to concrete to improve its properties. For example, some admixtures can make concrete more resistant to water penetration or freeze-thaw cycles.

Proper Curing of Concrete

Concrete must be properly cured to reach its full strength and durability. Curing involves keeping the concrete moist and protected from extreme temperatures. Curing is also necessary for the hydration process of cement to gain strength and maintain the temperature of the structure.